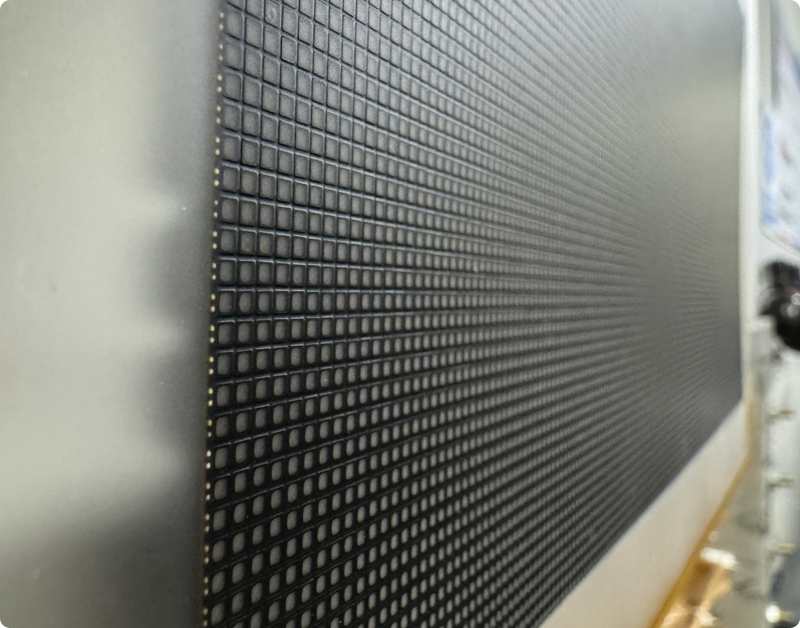

HOB Coating Protection Technology for LED Display Lamp Beads

When it comes to indoor and outdoor LED display performance, the reliability of lamp beads is

non-negotiable. HOB coating protection technology is a cutting-edge solution engineered to address

core

pain points of LED lamp beads, including moisture corrosion, dust accumulation, UV damage, and light

decay—critical for both commercial and industrial LED display applications.

Consult Now